We are committed to using a combination of proven and new-developing technologies to lead a new wave of chemical free natural ingredients to the market.

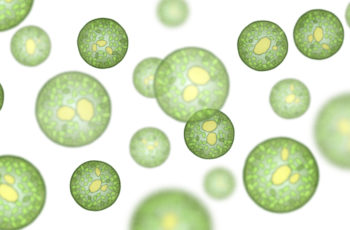

We provide high quality ingredients derived from algae.

Read More

We are committed to using a combination of proven and new-developing technologies to lead a new wave of chemical free natural ingredients to the market.

Our Company has developed a unique patented closed loop system to cultivate algae in a controlled environment. Cultivating the algae indoors enables us to have greater control of our process so that we can consistently deliver quality ingredients to our consumers. Our main objective is to provide our customers with the finest algae derived ingredients available in the marketplace.

Easy Process With Expert Guidance

Omega-3

Omega 3 Omega-3 fatty acids (typically thought of as ‘fish oil’) is one of the most important nutrients in the human diet. Fish don’t make these omega-3s, they have to consume them in their diet. So you’re probably wondering what ...

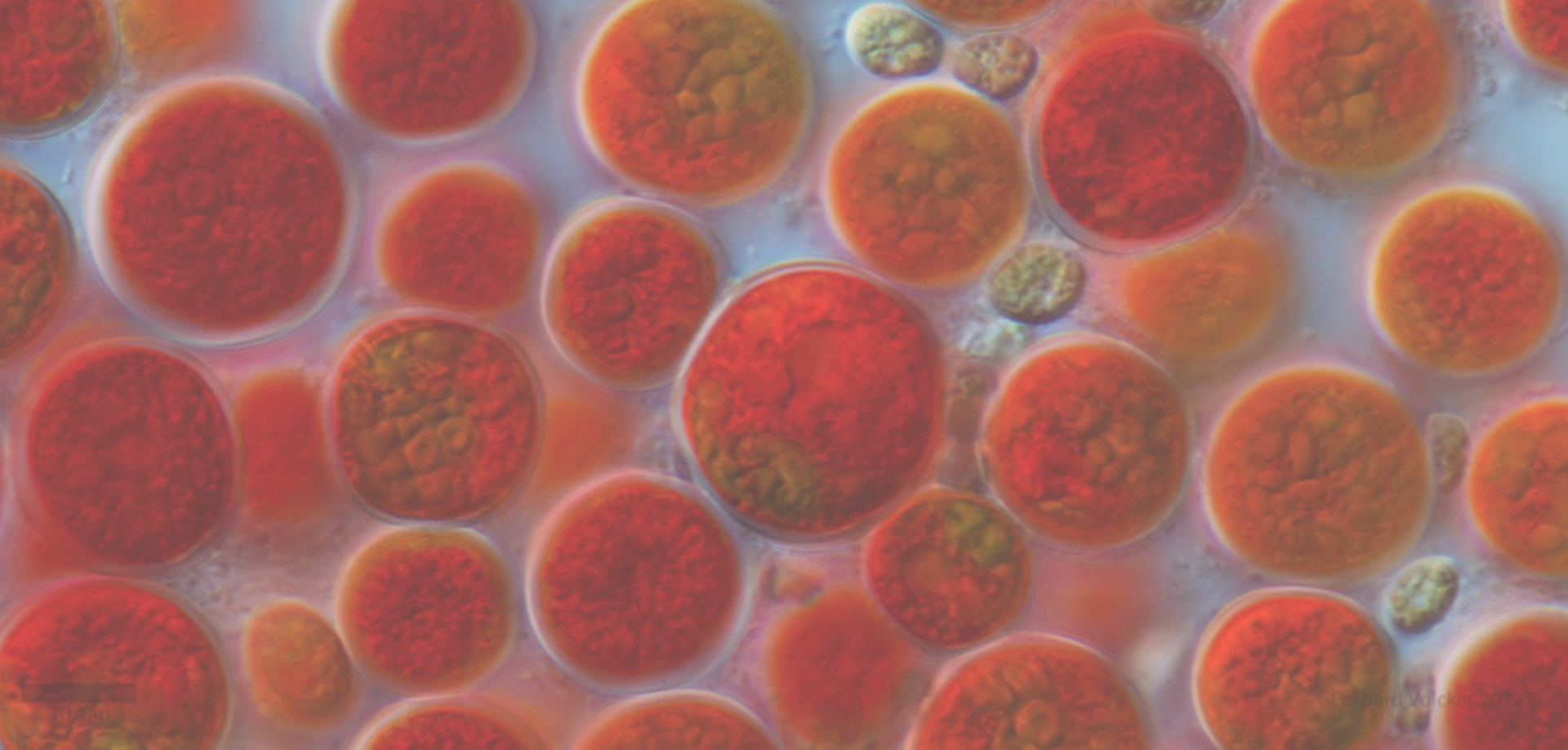

Learn MoreAstaxanthin

Astaxanthin If you find it difficult to pronounce astaxanthin, fear not. Although it isn’t part of the general American lexicon, it should be. You are probably consuming this amazing carotenoid and not even realizing it. Astaxanthin is that reddish pigment ...

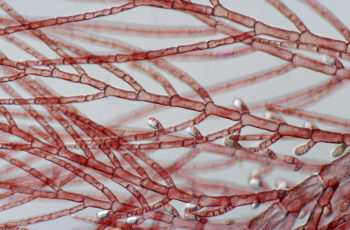

Learn MoreAnimal Feed

Animal Feed After the bulk algae biomass is processed for Omega 3 oil and Astaxanthin, the remaining dry algae cake serves as a nutritious and easily digestible feed for livestock – cattle, pigs, chicken and goats. It is price competitive ...

Learn MoreWhy Choose Us

High Quality

Ingredients

Unique

Closed Loop-System

The patented Omega Grow System generates faster algal growth rates versus less efficient open pond and non-continuous, closed-loop systems. Its modular design allows the flexibility to use any building or location for future production without having to modify or change the design.

Energy Efficient

Environmentally Sound

The patented Omega Grow System generates faster algal growth rates versus less efficient open pond and non-continuous, closed-loop systems. Its modular design allows the flexibility to use any building or location for future production without having to modify or change the design.

Learn more

about our

innovative methods

Watch Intro Video

Case Study

After the bulk algae biomass is processed for Omega 3 oil and Astaxanthin, the remaining dry algae cake serves as a nutritious and easily digestible feed for livestock – cattle, pigs, chicken and goats. It is price competitive with other feeds, environmentally friendly to produce and better than corn, which is difficult for cattle to digest.

24

Months

Increases egg laying period from 14 months to 24 months

2%

Decrease

Decreases mortality rates from 10% to less than 2%

87.9%

Highest hatchability

87.9% Highest Hatchability

Our Team

Focuses on providing the highest quality sustainably

sourced ingredients derived from algae.

Insights

Go to BlogAlgae to Omega Has the Technologies You Need

- Posted By admin

- 6 years ago

Because Algae to Omega recognizes the many benefits of algae ...

Algae Agriculture Act 2018

- Posted By admin

- 6 years ago

Algae to Omega has been a leader in the development ...

Algae’s Potential

- Posted By admin

- 6 years ago

Algae to Omega, a biotech company, has perfected the cultivation ...